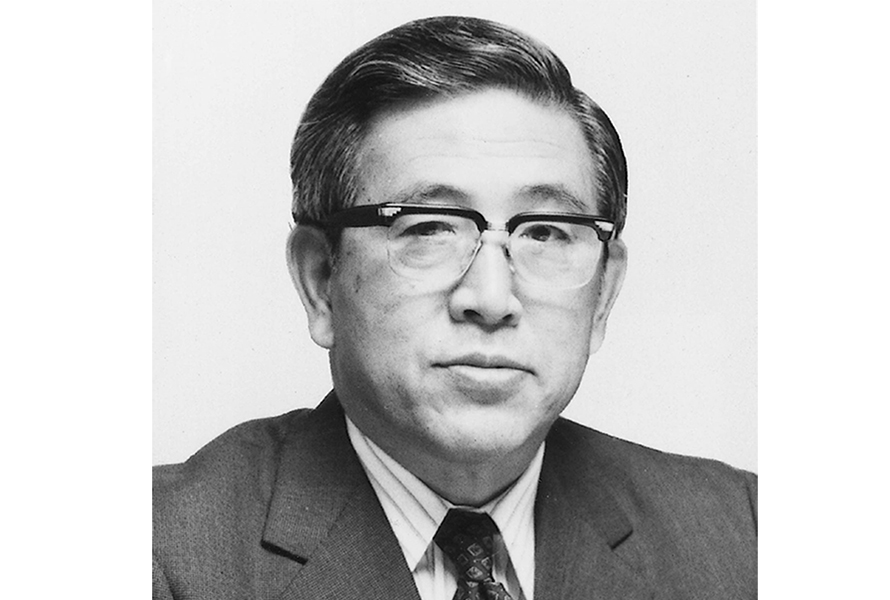

After the death of Kiichiro Toyoda, his son Shoichiro Toyoda was named the Successor-Toyota Crown Prince.

Shoichiro Toyoda was born in Nagoya on 17th February 1925, to Kiichiro and Hatako Toyoda. Being the eldest son in a traditional Japanese family firm, Shoichiro seemed destined to run the company from the time of his birth.

Growing up under the instruction of his mother, Shoichiro learned all that was going on in his father’s car and truck company, and he absorbed the lessons.

Shoichiro graduated from high school in 1945. He wanted to study engineering at Nagoya University, however World War II and the American occupation of Japan changed the destinies of both Toyota and of Shoichiro. At the time Kiichiro was making trucks for the Imperial Japanese Army, and his plant was within a few days of being bombed by American Boeing B-29 (B-29) when Japan surrendered. There might well have been no Toyota for his son Shoichiro to return to. Like many other young Japanese men, Shoichiro was recruited to labour in the fields, raising potatoes and barley to feed the army, navy, and civilian population. This interrupted his education and he did not receive his Bachelor of Science in Engineering until 1947.

Shoichiro then entered Tohoku University in Sendai, about five hundred miles north of Tokyo, where he continued his studies in engineering. He later married Hiroko Mitsui in 1952 and become the father of two children, which made him to not only focus on his academic growth but also family warfare. Notable, one of his greatest academic achievements was receiving a doctorate in the year 1955.

In the last years of Kiichiro’s life (his father), Toyota Japan Motor Company resumed making trucks and passenger cars. This was at the time when unionization was introduced to Japan byGeneral Douglas MacArthur, while F. Edwards Deming introduced quality control. The main purpose of unionization was to give workers/soldiers the power to negotiate for more favourable working conditions and other benefits through collective bargaining. Toyota then became unionized, and its workers demanded job security, which Kiichiro could not provide because the company was losing money.

Shoichiro had been ready to travel to America to manage a sewing-machine manufacturing operation, however, the passing of his father (Kiichiro) made him to change priorities. At the age of 27, he was made to run Toyota as a Director even when he was not ready. Undeniably, his young age coupled with knowledge he acquired form universities reviewed prosperity. Evidently, Toyota soon began to flourish by making trucks for the American army fighting in Korea.

SHOICHIRO CHAMPIONS TOTAL QUALITY CONTROL

The company presidency passed into the hands of Taizo Ishida, who was not a member of the Toyoda family. This proved to be an important lesson for Shoichiro; it showed him that Toyota could remain a family firm even when it was necessary temporarily to turn to someone outside the family to run the company.

The major influence on the maturing of Shoichiro was Eiji, who was at that time the most powerful family member in the company. Eiji guided Shoichiro as a young executive over two decades to shape him into his successor as company president. He gave Shoichiro his grand vision, to make Toyota a global automotive company, and training him to realize that vision.

Under Ishida, Toyota began to export cars to Europe and America. The Toyota Corona Crown was the first Japanese car to be marketed abroad. Its success in the 1950s and early 1960s was limited.

The Motomachi plant was opened in 1959 to produce Toyota cars. The director of the construction committee was Shoichiro, supervised by Eiji. Shoichiro was sent abroad to gain expertise on how to construct a plant for passenger cars. In 1961 he was promoted to managing director of the corporate planning office.

Shoichiro quickly recognized that Toyota’s cars and trucks were not of the quality foreign consumers were looking for. Americans would not buy what many of them saw as under-powered, unattractive, and undependable vehicles. Toyota would have to improve its entire production process, but doing so was easier said than done. While the company talked about improving quality control, it had little contact with American experts on the matter, and its workers were still inexperienced in this area.

Shoichiro saw a solution: Quality-control operations needed to be integrated into every step of production. They had to be systematic and a part of every Toyota department and operation. In the early 1960s he prevailed upon Eiji and Ishida to implement a total-quality-control program. The board agreed, and Shoichiro set the goal of having a program in operation by 1964. He brought in experts, but the company’s workers complained and revolted. Production expert Taiichi Ohno felt that Shoichiro was wasting his time and Toyota’s money. Within a year, though, Shoichiro’s critics knew he had been right. The number of defects in Toyota cars fell by half.

Taiichi Ohno a Japanese industrial engineer and businessman, who was considered to be the father of the Toyota Production System, which inspired Lean Manufacturing in the United States of America, devised the seven wastes as part of system of quality control. Toyota was on its way to global competitiveness and Shoichiro, more than any other individual, was responsible.

Shoichiro Toyoda is a retired Japanese business executive who served as chairman of Toyota Motor Corporation between 1992–1999, as well as chairman of the influential Japan Business Federation, beginning in May 1994 through May 1998. Today, he serves on the boards of a number of corporate and non-corporate organizations. He has been honorary chairman of the Japanese Federation of Economic Organizations (Nippon Keidanren) since 2002. In addition, he has received more than two dozen awards and medals in Japan, Europe, Asia, Australia and South America.